What Makes Active Harmonic Filters Indispensable for Modern Power Systems?

In an era where industries, commercial buildings, and critical infrastructure rely heavily on sensitive electronic equipment, maintaining clean and stable power has become a non-negotiable priority. Harmonics—distortions in the electrical current caused by non-linear loads like variable frequency drives, computers, and LED lighting—can lead to equipment failures, energy waste, and increased operational costs. Active Harmonic Filters have emerged as a cutting-edge solution to mitigate these issues, ensuring power systems operate efficiently and reliably. This guide explores why AHFs are essential for modern power systems, their working principles, detailed specifications of our advanced filters, and answers to common questions to highlight their transformative impact.

Trending News Headlines: Top Searches on Active Harmonic Filters

- "How Active Harmonic Filters Reduce Energy Costs in Data Centers"

- "Active Harmonic Filters: Ensuring Power Quality in Renewable Energy Systems"

These headlines underscore the versatility of AHFs—from industrial settings to renewable energy integration—highlighting their role in enhancing energy efficiency, reducing costs, and ensuring compliance with power quality standards. As industries transition to smarter, more electrified operations, the demand for AHFs continues to rise, making them a cornerstone of modern power management strategies.

Why Active Harmonic Filters Are Critical for Modern Power Systems

Eliminating Harmonic Distortion for Equipment Protection

Harmonics can cause significant damage to electrical equipment, including motors, transformers, and sensitive electronics. They increase heat generation, reduce equipment lifespan, and lead to unexpected failures. For example, in manufacturing facilities, harmonics from variable frequency drives (VFDs) can cause motor overheating, resulting in unplanned downtime and costly repairs. In data centers, where servers and cooling systems operate 24/7, harmonic distortion can disrupt power supply, leading to data loss or system crashes. AHFs actively monitor the electrical current, identify harmonic frequencies, and inject counteractive currents to cancel them out, ensuring the power supply remains clean. This protection extends equipment life, reduces maintenance costs, and minimizes downtime—critical for industries where operational continuity is paramount.

Improving Energy Efficiency and Reducing Costs

Harmonics not only damage equipment but also reduce the efficiency of power systems. They cause increased energy consumption, as electrical components must work harder to overcome distortion, leading to higher utility bills. Additionally, many utilities impose penalties for excessive harmonic distortion, adding to operational costs. AHFs mitigate these issues by reducing harmonic currents, which lowers energy losses in cables, transformers, and other components. Studies have shown that AHFs can reduce energy consumption by 5-15% in facilities with high non-linear loads, such as factories, data centers, and commercial buildings. Over time, these savings offset the initial investment in the filters, making them a cost-effective solution for long-term energy management.

Ensuring Compliance with Power Quality Standards

Regulatory bodies worldwide, such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), have established strict standards for power quality, including limits on harmonic distortion (e.g., IEEE 519). Non-compliance can result in fines, legal liabilities, and even disconnection from the power grid in severe cases. Active Harmonic Filters ensure that facilities meet these standards by keeping harmonic distortion within acceptable limits. This is particularly important for industries that rely on grid connectivity, such as renewable energy plants (solar, wind) and large commercial complexes, where harmonic emissions can affect neighboring users. By maintaining compliance, businesses avoid penalties and foster good relationships with utilities and the community.

Supporting the Integration of Renewable Energy and Smart Grids

The global shift toward renewable energy sources (solar, wind) and smart grid technologies has introduced new challenges to power systems. Inverters used in renewable energy systems are non-linear loads that generate harmonics, while smart grids require stable power quality to function optimally. AHFs play a crucial role in integrating these technologies by mitigating harmonics from renewable energy systems, ensuring they do not disrupt the grid. They also enhance the stability of smart grids by maintaining clean power, enabling efficient communication between grid components and supporting advanced features like demand response and energy management. As renewable energy adoption grows, AHFs will become increasingly vital for maintaining grid reliability and sustainability.

Enhancing System Reliability and Reducing Downtime

Unplanned downtime due to power quality issues can cost businesses thousands of dollars per hour, depending on the industry. For example, in semiconductor manufacturing, a single power disruption can ruin an entire batch of microchips, resulting in massive losses. AHFs enhance system reliability by preventing voltage fluctuations, overheating, and equipment failures caused by harmonics. By ensuring a stable power supply, they minimize downtime, protect critical processes, and maintain productivity. This reliability is especially valuable for mission-critical facilities like hospitals, where power interruptions can threaten patient safety, and financial institutions, where even short outages can lead to data loss and financial penalties.

How Active Harmonic Filters Work

Harmonic Detection

The filter continuously monitors the electrical current and voltage in the power system using high-precision sensors. A dedicated microprocessor analyzes the waveform to identify harmonic components—typically odd multiples of the fundamental frequency (50Hz or 60Hz), such as 3rd, 5th, 7th, and 11th harmonics. Advanced algorithms process the data to determine the amplitude and phase of each harmonic, ensuring accurate detection even in complex systems with multiple non-linear loads.

Signal Processing and Calculation

Once harmonics are detected, the microprocessor calculates the exact magnitude and phase of the counteractive current needed to cancel each harmonic. This calculation is performed in real time (within microseconds) to ensure the filter responds immediately to changes in the load profile. The processor also accounts for system parameters like voltage level, frequency, and load variations to optimize performance.

Current Injection

The filter generates the calculated counteractive current using a power inverter, which converts DC power (from an internal capacitor bank or external power supply) into AC current with the same frequency and amplitude as the detected harmonics but with an opposite phase. This countercurrent is injected into the power system, effectively canceling out the harmonic distortion and leaving a clean, sinusoidal current.

Adaptive Control

Modern AHFs feature adaptive control systems that adjust their operation based on changing load conditions. They can handle dynamic loads (e.g., varying motor speeds in manufacturing) by continuously updating their harmonic detection and current injection parameters. Some advanced models also include communication capabilities, allowing them to be integrated into building management systems (BMS) or industrial control systems (ICS) for remote monitoring and optimization.

Our Active Harmonic Filter Specifications

|

Feature

|

GY-AHF-100 (Single-Phase)

|

GY-AHF-400 (Three-Phase)

|

GY-AHF-1000 (Industrial Heavy-Duty)

|

|

Rated Voltage

|

220V AC ±10%

|

380V AC ±15%

|

400V/690V AC ±15%

|

|

Rated Current

|

100A

|

400A

|

1000A

|

|

Harmonic Compensation Range

|

2nd–50th harmonics

|

2nd–50th harmonics

|

2nd–50th harmonics

|

|

Compensation Efficiency

|

≥97%

|

≥98%

|

≥98.5%

|

|

Response Time

|

<200μs

|

<150μs

|

<100μs

|

|

THD Reduction

|

From >30% to <5%

|

From >30% to <3%

|

From >30% to <2%

|

|

Power Factor Correction

|

0.95–1.0 (leading/lagging)

|

0.95–1.0 (leading/lagging)

|

0.95–1.0 (leading/lagging)

|

|

Cooling Method

|

Natural convection + forced air

|

Forced air

|

Liquid cooling

|

|

Operating Temperature

|

-10°C to +40°C

|

-10°C to +50°C

|

-20°C to +60°C

|

|

Protection Features

|

Overcurrent, overvoltage, short circuit, overtemperature

|

Overcurrent, overvoltage, short circuit, overtemperature, phase loss

|

Overcurrent, overvoltage, short circuit, overtemperature, phase loss, ground fault

|

|

Communication Interfaces

|

RS485 (Modbus RTU)

|

RS485 (Modbus RTU), Ethernet (Modbus TCP/IP)

|

RS485 (Modbus RTU), Ethernet (Modbus TCP/IP), Profibus

|

|

Dimensions (W×H×D)

|

300×450×200 mm

|

600×800×300 mm

|

800×1200×600 mm

|

|

Weight

|

15 kg

|

50 kg

|

200 kg

|

|

Certifications

|

CE, RoHS

|

CE, RoHS, UL

|

CE, RoHS, UL, IEC 61000-3-2

|

|

Warranty

|

2 years

|

3 years

|

5 years

|

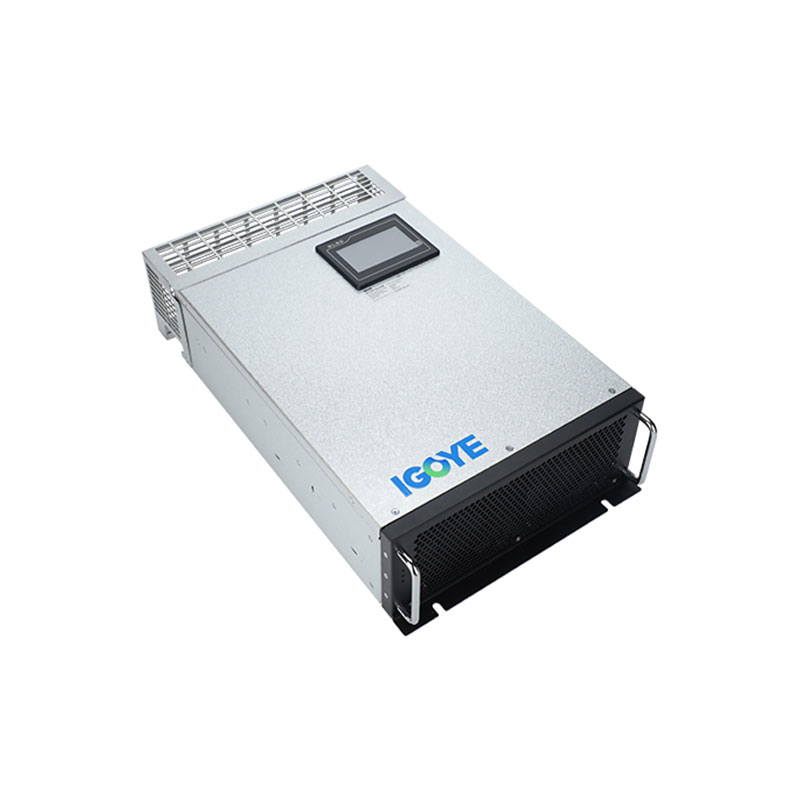

All our Active Harmonic Filters are designed to meet international standards, ensuring compliance with IEEE 519, IEC 61000-3-2, and other global regulations. They also include user-friendly features, such as intuitive touchscreen interfaces, remote monitoring capabilities, and automatic self-diagnosis, making them easy to install, operate, and maintain.

FAQ: Common Questions About Active Harmonic Filters

- Benefits of Using Active Harmonic Filters

- Why Is an Advanced Static Var Generator Becoming Essential for Modern Power Systems?

- Why did a cabinet-type active harmonic filter change the way my plant handles power quality?

- What makes a wall-mounted static var generator the smart fix for unstable power?

- Can Your Facility Meet Strict Grid Regulations with a Cabinet-Type Static Var Generator

- Does a Rack Mount Active Harmonic Filter Protect Against Transformer Damage