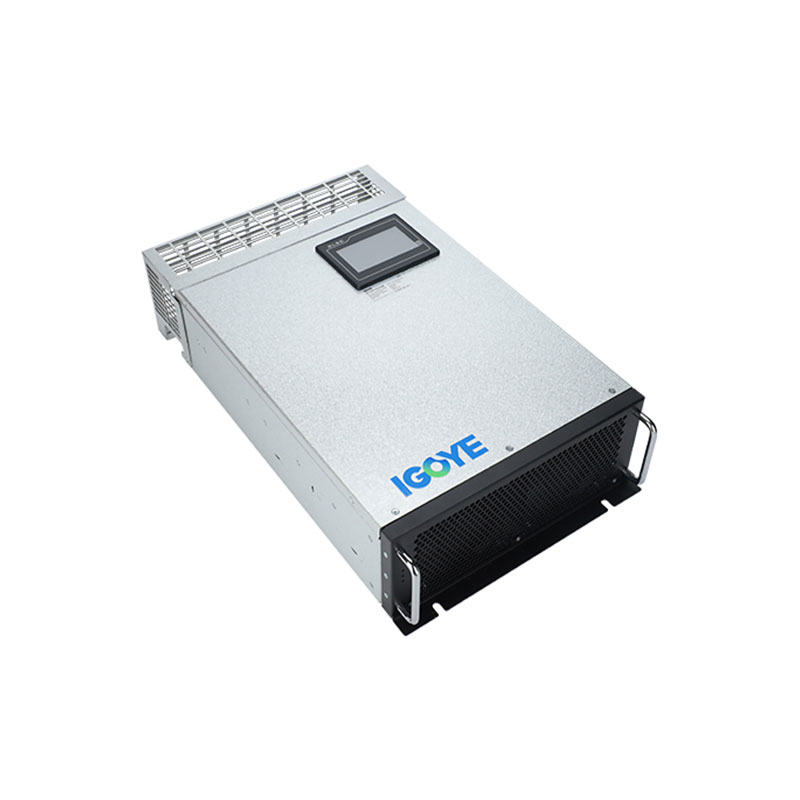

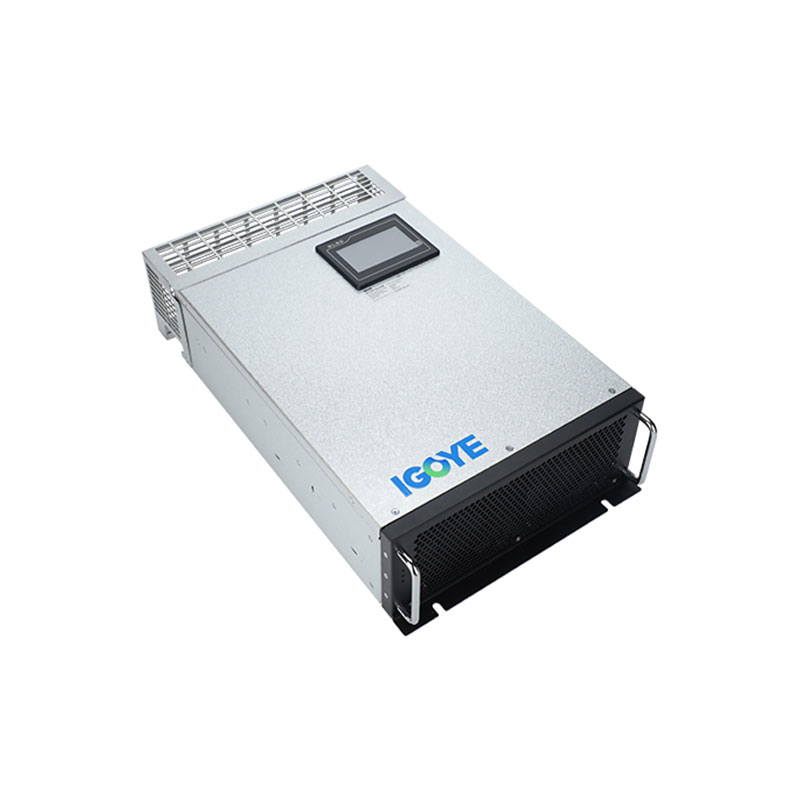

Cabinet-type Active Harmonic Filter

Why Pick GEYA Cabinet-type Active Harmonic Filter?

Tough Build – Endures harsh industrial settings.

Smart Tech – Uses cutting-edge power electronics.

Tailored Fit – Adapts to specific system needs.

Global Approval – Meets CE, C-Tick, and more.

Applications

Factories – Scrubs harmonics from VFDs and UPS.

Offices – Cleans power, cuts energy waste.

Data Centers – Secures steady IT power.

Renewables – Clears distortions from solar and wind.

FAQ

1.What is the function of active harmonic filter?

An AHF erases harmonics in real time, sharpening power quality.

· Live Tracking – Scans waveforms for distortions.

· Instant Correction – Fires counter-currents to nullify harmonics.

· Multi-Tasking – Handles harmonics, reactive power, and imbalances.

· Self-Adjusting – Adapts to load shifts, no manual tweaks needed.

· Power Saver – Cuts transformer and cable losses, slashes costs.

· Gear Shield – Blocks overheating, prevents motor and capacitor failures.

· Grid Safe – Stabilizes voltage, meets strict power rules.

2. What is the heat loss of the active harmonic filter?

Heat loss depends on the AHF’s rated capacity and operating load. Typically, losses range from 2% to 5% of the filter’s rated power due to IGBT switching and inductor/capacitor inefficiencies. Proper ventilation is critical for performance.

3. How does Cabinet-type Active Harmonic Filter work?

Detection: Sensors measure load current harmonics.

Analysis: The controller identifies harmonic frequencies (e.g., 5th, 7th, 11th).

Compensation: The inverter produces equal-but-opposite harmonic currents using PWM switching.

Injection: These currents are fed back into the system, neutralizing harmonics.

- View as

690V Cabinet-type Active Harmonic Filter

500V Cabinet-type Active Harmonic Filter

380V Cabinet-type Active Harmonic Filter

220V Cabinet-type Active Harmonic Filter

Three-phase Four-wire Cabinet-type Active Harmonic Filter