How Rack Mount Active Harmonic Filters Optimize Power Quality and Efficiency

In today’s rapidly evolving industrial and commercial environments, power quality has become a critical factor influencing productivity, equipment performance, and operational costs. With the increasing use of non-linear loads like variable frequency drives (VFDs), data servers, robotics, and LED lighting systems, harmonic distortion in power networks has become a common challenge. One of the most effective solutions to mitigate harmonics and improve energy efficiency is the Rack Mount Active Harmonic Filter (AHF).

What Is a Rack Mount Active Harmonic Filter and Why It Matters

A Rack Mount Active Harmonic Filter is an intelligent electronic device designed to detect, analyze, and dynamically compensate harmonic distortions in an electrical network. Unlike passive filters, which are tuned to specific harmonic frequencies, active harmonic filters provide real-time correction across multiple harmonic orders, ensuring stable and clean power.

Why Harmonics Are a Problem

Harmonics are unwanted high-frequency signals in an electrical system, typically generated by non-linear loads like:

-

Variable Frequency Drives (VFDs)

-

UPS systems and data centers

-

LED and fluorescent lighting

-

Computer servers and IT equipment

-

Industrial automation and robotics

If left untreated, harmonics can cause:

-

Overheating of transformers, motors, and cables

-

Reduced power factor and higher energy bills

-

Unstable operation of sensitive equipment

-

Increased maintenance costs due to equipment wear

Why Choose Rack Mount AHFs Over Other Solutions

Compared to passive filters and traditional mitigation techniques, rack-mounted AHFs offer:

-

Real-time harmonic detection and compensation

-

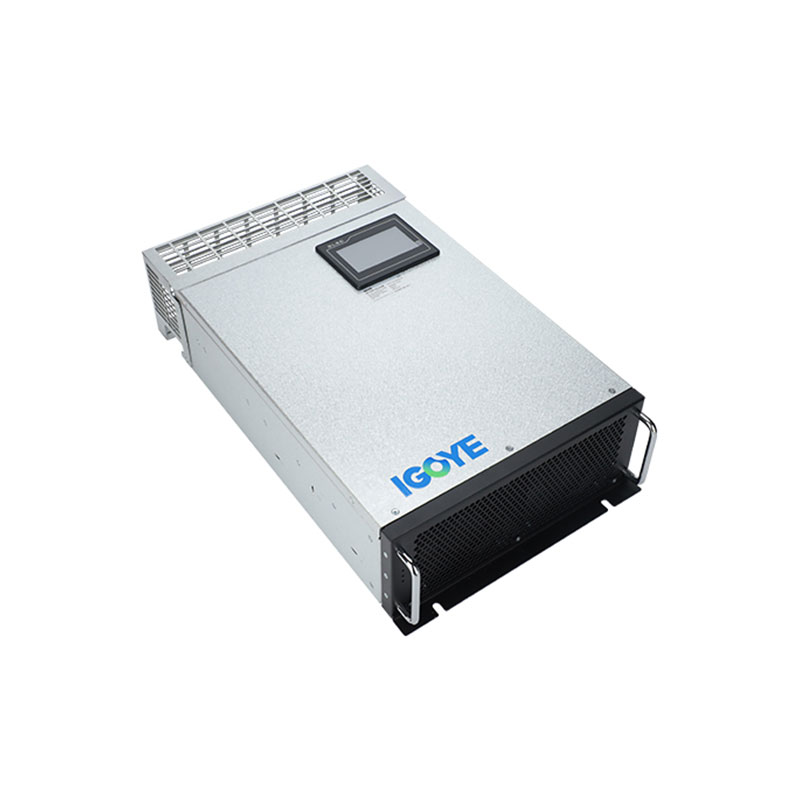

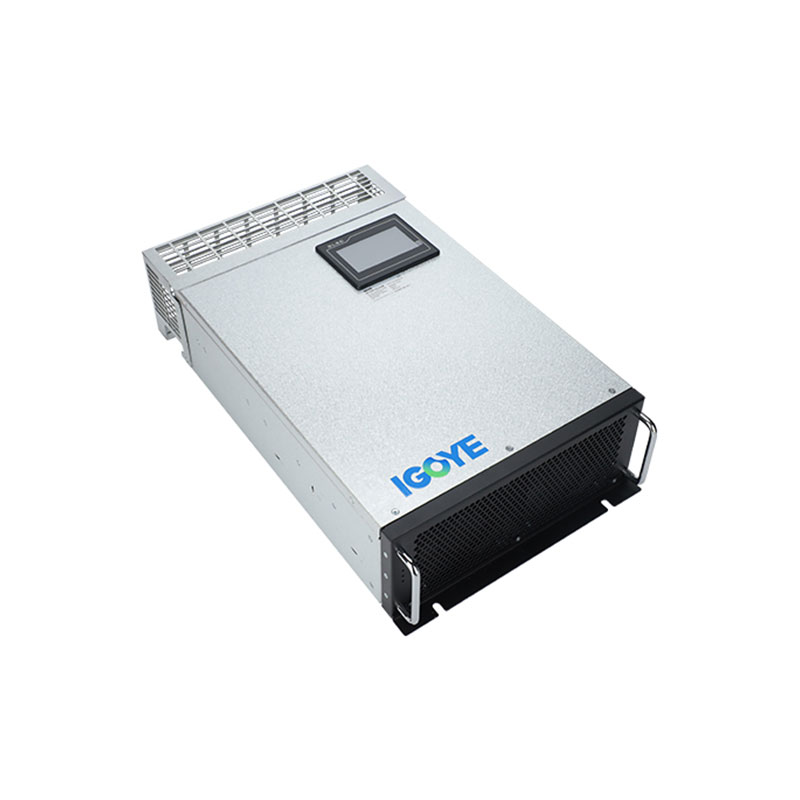

Compact rack-mount design ideal for data centers and control rooms

-

Automatic adjustment to varying load conditions

-

Scalability for small to large electrical networks

-

Compliance with IEEE-519, IEC61000, and EN50160 power quality standards

In short, installing a Rack Mount Active Harmonic Filter ensures a stable, efficient, and compliant power network.

How Rack Mount Active Harmonic Filters Work

Rack mount AHFs function using advanced power electronics and microprocessor-based control systems. They continuously monitor the power network, analyze current waveforms, and inject counter-currents to neutralize unwanted harmonics.

Working Principle

-

Real-Time Sensing – The AHF measures current and voltage signals in the electrical system.

-

Harmonic Detection – Using FFT-based algorithms, the filter identifies harmonic components.

-

Compensation – The AHF generates equal and opposite harmonic currents, effectively canceling distortions.

-

Dynamic Response – The system adapts instantly to load variations without manual intervention.

This process occurs in less than one cycle (20ms for 50Hz), ensuring continuous and accurate harmonic mitigation.

Technical Advantages

-

High filtering capacity: Up to the 50th harmonic order

-

Low response time: <20ms

-

Configurable compensation levels: Adjustable from 25% to 100%

-

Modular scalability: Multiple units can be paralleled

-

Easy integration: Rack-mountable design with plug-and-play installation

Product Specifications and Professional Features

Below is an overview of the key specifications for a standard Rack Mount Active Harmonic Filter:

| Parameter | Specification |

|---|---|

| Rated Voltage | 208V / 380V / 400V / 480V |

| Rated Current | 30A / 50A / 75A / 100A |

| Compensation Capacity | 30kVAR – 120kVAR |

| Response Time | < 20ms |

| Harmonic Filtering | Up to the 50th order |

| Power Factor Correction | Up to 0.99 |

| Communication Ports | RS485 / Modbus / Ethernet |

| Mounting Type | 19-inch rack-mount |

| Cooling Method | Forced air cooling |

| Standards Compliance | IEEE-519, IEC61000, EN50160 |

Key Highlights

-

Compact rack size: Perfect for space-constrained environments like server rooms and data centers

-

Intelligent monitoring: Integrated LCD display and IoT-based remote access

-

Energy efficiency: Reduces losses and lowers total electricity costs

-

Reliability: Designed with redundant protection mechanisms for long-term stability

Applications and Benefits Across Industries

Rack mount AHFs are versatile and widely used in sectors where clean power and system reliability are critical.

Typical Applications

-

Data Centers – Prevent server downtime caused by voltage fluctuations

-

Manufacturing Plants – Protect sensitive automation and control systems

-

Healthcare Facilities – Stabilize medical imaging and diagnostic equipment

-

Commercial Buildings – Improve elevator, lighting, and HVAC efficiency

-

Renewable Energy Systems – Enhance inverter-based solar and wind installations

Key Benefits

-

Enhanced Equipment Life – Minimized overheating and stress on components

-

Reduced Energy Costs – Improved power factor and lower energy losses

-

Regulatory Compliance – Meets strict harmonic standards globally

-

Future-Ready Design – Supports Industry 4.0 integration and IoT monitoring

Frequently Asked Questions (FAQs)

Q1. How does a Rack Mount Active Harmonic Filter improve energy efficiency?

An AHF actively compensates for unwanted harmonics and improves the power factor. By reducing reactive power and eliminating harmonic losses, facilities achieve lower energy bills and improved operational efficiency.

Q2. What size of Rack Mount Active Harmonic Filter should I choose?

It depends on your load profile, voltage level, and harmonic distortion levels. For example, a 30A rack-mounted AHF is ideal for small IT rooms, while a 100A unit suits larger industrial environments. A detailed power quality analysis helps determine the optimal capacity.

Why Choose GEYA Rack Mount Active Harmonic Filters

GEYA specializes in cutting-edge power quality solutions designed for modern electrical infrastructures. Our Rack Mount Active Harmonic Filters combine advanced digital control, compact design, and industry compliance to deliver superior harmonic mitigation and energy efficiency.

-

Over 15 years of expertise in power quality optimization

-

High-precision real-time harmonic compensation

-

Global compliance with IEEE and IEC standards

-

Reliable after-sales support and IoT-enabled monitoring

For businesses seeking stable, efficient, and future-ready power systems, GEYA provides customized AHF solutions tailored to your needs.

Contact us today to learn more about GEYA’s Rack Mount Active Harmonic Filters and how we can help you enhance power quality, reduce energy losses, and protect your critical equipment.

- Benefits of Using Active Harmonic Filters

- Why Is an Advanced Static Var Generator Becoming Essential for Modern Power Systems?

- Why did a cabinet-type active harmonic filter change the way my plant handles power quality?

- What makes a wall-mounted static var generator the smart fix for unstable power?

- Can Your Facility Meet Strict Grid Regulations with a Cabinet-Type Static Var Generator

- Does a Rack Mount Active Harmonic Filter Protect Against Transformer Damage