Benefits of Using Active Harmonic Filters

In today's fast-paced industrial world, energy efficiency is more important than ever. Businesses strive to reduce costs and improve sustainability. One key technology that aids in this pursuit is the Active Harmonic Filter.

Active Harmonic Filters (AHFs) are essential for modern electrical systems. They help mitigate harmonic distortion, a common issue in power networks. Harmonic distortion can lead to inefficiencies and increased energy costs.

By using AHFs, companies can significantly improve their power factor. A better power factor means more efficient use of electrical power. This efficiency translates into reduced energy waste and lower utility bills.

AHFs are particularly beneficial in settings with non-linear loads. These include variable frequency drives and rectifiers. Such environments often experience significant harmonic distortion.

The benefits of AHFs extend beyond energy savings. They also enhance the lifespan of electrical equipment. By improving power quality, AHFs prevent overheating and equipment failure.

Moreover, AHFs help facilities comply with international power quality standards. Compliance is crucial for maintaining operational efficiency and avoiding penalties. AHFs offer a dynamic solution, adjusting to changes in load conditions.

This adaptability ensures real-time harmonic mitigation. As a result, businesses experience fewer equipment malfunctions and downtime. AHFs are a cost-effective solution compared to passive filters.

They integrate seamlessly into existing systems without major modifications. This ease of integration makes them a popular choice for many industries. From manufacturing plants to data centers, AHFs are versatile.

Incorporating AHFs into energy management strategies can lead to significant savings. They contribute to a more sustainable and environmentally friendly operation. As technology evolves, AHFs continue to offer more efficient solutions.

In summary, Active Harmonic Filters are vital for improving power quality. They support energy efficiency and reduce operational costs. For businesses aiming to optimize their electrical systems, AHFs are indispensable.

Understanding Harmonics in Electrical Systems

Harmonics are an inevitable part of modern electrical systems. They are created by non-linear loads, which are common in today's industries. Understanding harmonics is crucial to maintaining power quality.

Non-linear loads distort the current waveforms in electrical systems. These distortions create harmonics, which are multiples of the fundamental frequency. Harmonics can cause several issues if not managed properly.

One primary consequence is increased energy losses. Harmonic distortion leads to inefficient power usage. It results in higher energy bills and reduced system performance.

Besides energy waste, harmonics can cause equipment overheating. Motors and transformers are particularly vulnerable to this issue. Overheating can shorten equipment life and lead to unexpected downtime.

Harmonics can also cause resonance in electrical circuits. Resonance amplifies the effects of harmonics and worsens power quality. It can lead to voltage fluctuations and equipment malfunctions.

To tackle these issues, it's important to identify harmonic sources. Common sources include variable frequency drives, rectifiers, and other electronic devices. Equipment connected to the grid often contributes to harmonic distortion.

Managing harmonics involves various strategies. Some focus on reducing harmonic emission at the source. This can be achieved through equipment design improvements and updated technologies.

Others employ filtering techniques to mitigate harmonics in power systems. Active Harmonic Filters (AHFs) are a powerful tool in this regard. They dynamically compensate for harmonics and improve power quality.

Strategies for Harmonic Management:

- Source identification and elimination

- Equipment design improvements

- Use of Active Harmonic Filters

- Regular system monitoring

- Optimization of power usage

Regular monitoring of power systems helps in early detection of issues. Timely intervention can prevent serious consequences and ensure system stability. Monitoring also allows for real-time adjustments and optimization of energy usage.

Understanding the root causes of harmonics is vital. Effective management not only reduces costs but also enhances reliability. A proactive approach ensures a safer and more efficient electrical environment.

In summary, comprehending harmonics in electrical systems is essential for improving power quality and efficiency. Proper management strategies protect equipment and enhance operational performance. Active Harmonic Filters play a crucial role in this, offering both dynamic compensation and compliance with power standards.

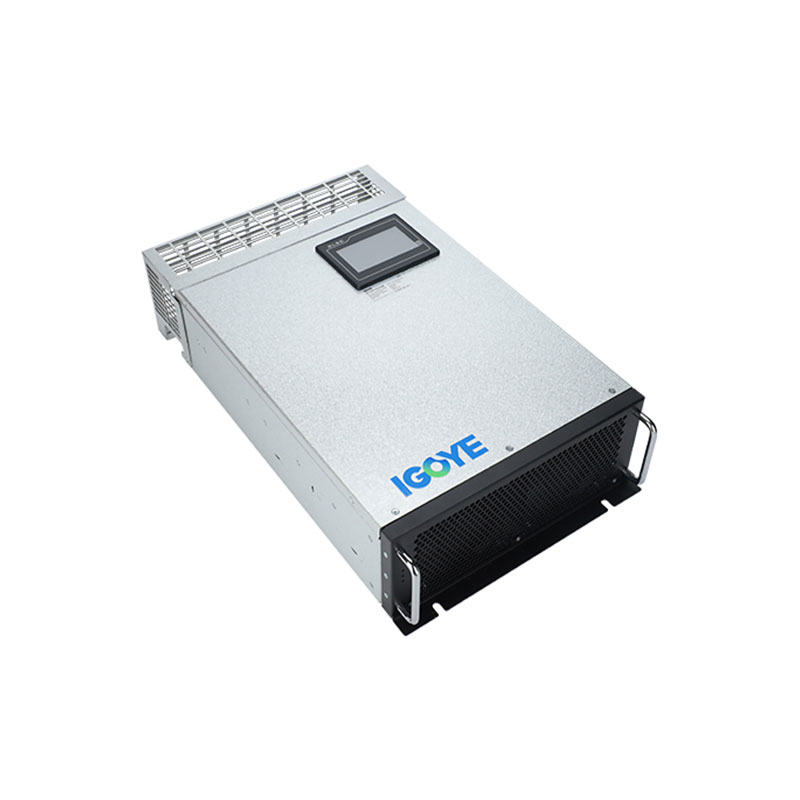

What Are Active Harmonic Filters?

Active Harmonic Filters (AHFs) are essential devices in modern electrical systems. They address problems caused by harmonics, enhancing overall power quality.

AHFs function by injecting counter-currents into the system. This process neutralizes harmonics and reduces their impact. Unlike passive filters, AHFs can adapt to changing load conditions.

AHFs are particularly beneficial in systems with dynamic loads. They automatically adjust to harmonic variations, ensuring continuous protection. This adaptability makes them superior to traditional solutions.

One key feature of AHFs is their real-time response capability. They monitor harmonic levels and adjust accordingly. This ensures constant power quality without manual intervention.

Benefits of Active Harmonic Filters:

- Real-time harmonic mitigation

- Improved energy efficiency

- Enhanced power factor

- Equipment protection

- Adaptability to dynamic loads

AHFs improve energy efficiency by minimizing power losses. By compensating for harmonics, they optimize the use of electrical power. This leads to significant energy savings.

Another advantage is improved power factor. AHFs correct the power factor, reducing demand charges. This also prevents penalties from utility providers.

Additionally, AHFs protect equipment from harmonic-related issues. They prevent overheating and reduce wear on electrical components. This extends equipment lifespan and reduces maintenance costs.

In terms of installation, AHFs are versatile. They can be integrated into existing systems with minimal modifications. This ease of integration makes them a cost-effective solution.

In summary, Active Harmonic Filters are a robust tool for improving power quality. Their ability to dynamically manage harmonics makes them indispensable in modern electrical environments. By enhancing energy efficiency and protecting equipment, AHFs offer both financial and operational benefits.

How Active Harmonic Filters Work

Active Harmonic Filters (AHFs) use advanced technology to tackle harmonic issues in power systems. They dynamically analyze power quality and respond in real-time. This capability sets them apart from their passive counterparts.

AHFs operate by measuring the harmonic distortion present in the electrical system. They use sensors to detect specific harmonic frequencies. This data collection is continuous, providing live feedback on system conditions.

Once the AHFs detect harmonic distortions, they generate counter-currents. These counter-currents are precisely engineered to cancel out the existing harmonics. This process is known as active harmonic compensation.

by Andrei Castanha (https://unsplash.com/@andreicastanha)

by Andrei Castanha (https://unsplash.com/@andreicastanha)

The AHF's rapid response is enabled by advanced processors. These processors analyze the incoming data, determining the best corrective actions. This quick analysis is crucial for effective harmonic mitigation.

Key Features of Active Harmonic Filters:

- Real-time harmonic detection

- Immediate compensation with counter-currents

- High-frequency response capability

- Dynamic adaptability to load changes

- Advanced monitoring and control systems

AHFs differ from passive filters mainly in their adaptability. Passive filters work on fixed harmonic frequencies, which limits their effectiveness. AHFs can adjust to different harmonic spectrums, enhancing their versatility.

Moreover, AHFs are designed to handle a wide range of harmonic orders. They can mitigate both low and high-order harmonics effectively. This comprehensive approach ensures better protection and improved power quality.

In addition to harmonic mitigation, AHFs can also improve the power factor. By managing reactive power, they enhance overall system efficiency. This dual function increases their value in power management strategies.

AHFs also support remote monitoring and management. They can be integrated with supervisory control systems. This integration allows for easier maintenance and system adjustments.

Finally, AHFs contribute significantly to system reliability. By preventing harmonic-related failures, they enhance the lifespan of electrical equipment. This leads to fewer disruptions and better operational stability.

In conclusion, Active Harmonic Filters are an integral part of modern power systems. Their ability to dynamically and effectively manage harmonics greatly enhances power quality. By employing advanced technology, they ensure both energy efficiency and system reliability, making them a wise investment for any facility.

Key Benefits of Using Active Harmonic Filters

Active Harmonic Filters (AHFs) offer numerous benefits in electrical systems. They address challenges associated with power quality and energy efficiency. These benefits extend to cost savings and system reliability.

One of the primary advantages of AHFs is their ability to improve energy efficiency. By reducing harmonic distortion, they optimize power use. This optimization leads to noticeable reductions in energy waste.

Another significant benefit is enhanced power factor correction. Poor power factor can lead to high utility costs. AHFs help by minimizing reactive power and thus improving the overall power factor.

AHFs also play a crucial role in protecting equipment. Harmonic distortions can cause overheating and equipment failures. By reducing distortion, AHFs extend the life of electrical components.

Moreover, AHFs ensure compliance with important power quality standards. Standards like IEEE 519 set limits on harmonic distortion. Compliance is crucial for avoiding penalties and ensuring safety.

In terms of investment, AHFs offer excellent return on investment (ROI). They lead to energy cost savings and reduced maintenance expenses. The initial cost is often offset by these ongoing savings.

Improved Energy Efficiency

AHFs contribute significantly to energy efficiency. They achieve this by lowering total harmonic distortion (THD). Lower THD means less wasted power in electrical systems.

Energy efficiency leads to reduced electricity consumption. This reduction positively impacts operational costs. Facilities can notice substantial savings over time.

Additionally, AHFs help in optimizing the distribution of electrical power. Effective distribution ensures that energy is used more effectively. This optimization helps facilities meet their sustainability goals.

Factors contributing to enhanced energy efficiency include:

- Lowering total harmonic distortion

- Reducing energy wastage

- Optimizing power distribution

- Minimizing overheating in electrical components

These improvements are particularly beneficial in industries with high power demands. Facilities can achieve significant reductions in energy expenses. This makes AHFs a valuable tool for energy managers.

Enhanced Power Factor Correction

Power factor correction is another crucial advantage of AHFs. Poor power factor leads to increased demand charges from utilities. By enhancing the power factor, AHFs reduce these charges.

AHFs achieve this by addressing reactive power issues. Reactive power does not perform useful work but affects power quality. AHFs mitigate these effects, enhancing overall system efficiency.

Benefits of improved power factor include:

- Reduced demand charges

- Better efficiency in power usage

- Decreased strain on electrical infrastructure

- Lower operational costs

AHFs dynamically adapt to changes in load conditions. This adaptability ensures optimal power factor correction at all times. As a result, facilities enjoy continuous financial and operational benefits.

Superior Power Quality and Equipment Protection

AHFs are instrumental in improving power quality. High power quality is essential for uninterrupted operations. Poor quality can lead to unexpected outages and equipment failures.

Harmonic distortions cause excessive heating and wear in components. By eliminating these distortions, AHFs protect valuable equipment. Protection reduces maintenance needs and extends equipment lifespan.

Aspects of power quality improvements by AHFs include:

- Reduction in harmonic distortions

- Prevention of overheating and failures

- Prolonged equipment lifespan

- Fewer operational disruptions

These benefits contribute to maintaining a stable electrical environment. This stability translates to reliable production and service delivery. Thus, AHFs are vital for facilities prioritizing continuous operations.

Compliance with Power Quality Standards

Compliance with international standards is another critical aspect. Standards like IEEE 519 set limits on allowable harmonic distortion. AHFs help facilities adhere to these regulatory requirements.

Non-compliance can result in penalties and even equipment damage. AHFs ensure facilities maintain acceptable THD levels. This compliance ensures operational safety and legal adherence.

Key compliance features provided by AHFs:

- Maintaining THD below permissible levels

- Ensuring adherence to regulatory standards

- Protecting against non-compliance penalties

- Enhancing safety of electrical systems

By using AHFs, facilities can confidently meet regulatory expectations. This compliance not only avoids penalties but also ensures operational integrity. Thus, AHFs are essential for any facility looking to comply with these global standards.

Cost Savings and Return on Investment

Cost savings is a compelling argument for the implementation of AHFs. By reducing energy consumption, facilities can see instant savings. These savings quickly accumulate, justifying the initial purchase costs.

AHFs also reduce maintenance costs associated with electrical equipment. With fewer distortions, equipment is less prone to failures. This reliability reduces the necessity for frequent repairs and replacements.

by Ibrahim Rifath (https://unsplash.com/@ripey__)

by Ibrahim Rifath (https://unsplash.com/@ripey__)

Reasons for enhanced cost savings include:

- Lower electricity bills due to improved efficiency

- Reduced maintenance and repair expenses

- Decrease in operational disruptions and downtime

- Return on investment through accumulated savings

Over time, the cost benefits of AHFs become increasingly apparent. The reduced energy waste and maintenance costs lead to enhanced profitability. For any facility aiming at financial sustainability, AHFs are a wise investment.

Applications of Active Harmonic Filters

Active Harmonic Filters (AHFs) are versatile tools in modern electrical systems. Their applications span various industries and environments. These filters improve power quality in diverse settings.

One prominent application is in industrial facilities. These facilities often employ variable frequency drives and rectifiers. Such equipment introduces significant harmonic distortion into the power system.

AHFs are also vital in commercial buildings. These buildings typically have complex electrical networks. Ensuring high power quality is essential to avoid downtimes and enhance energy efficiency.

Data centers represent another critical area for AHF application. These centers require uninterrupted power for continuous operation. AHFs help by maintaining power stability and reducing harmonic losses.

In hospitals, where reliable power supply is crucial, AHFs ensure that medical equipment functions optimally. Harmonic distortions could lead to equipment malfunction, affecting patient care.

by Eyestetix Studio (https://unsplash.com/@eyestetix)

by Eyestetix Studio (https://unsplash.com/@eyestetix)

Additionally, AHFs play a role in renewable energy systems. They help manage the power quality issues that arise with integrating solar or wind energy. As renewable sources vary in output, AHFs adjust to the changes, ensuring consistent power quality.

The automotive industry also benefits from AHFs. With the increasing automation and use of electric systems, maintaining power integrity becomes critical. AHFs reduce the risk of malfunctions due to power quality issues.

Lastly, AHFs are advantageous in airports and other critical infrastructure sectors. They ensure that essential services run smoothly without power disruptions. This reliability is vital for operations that cannot afford downtime.

In summary, AHFs are adaptable to various sectors with unique power quality needs. They provide solutions that help maintain system reliability and efficiency across different applications. Their benefits are clear as industries continue seeking ways to improve operational efficiencies and sustainability.

Comparing Active and Passive Harmonic Filters

Active and passive harmonic filters both aim to improve power quality. However, they differ significantly in their approach and effectiveness. Understanding these differences is crucial for informed decision-making.

Active Harmonic Filters (AHFs) dynamically monitor and compensate for harmonic distortion. They operate in real-time, adapting to changes in load conditions. This makes them highly effective in varied and unpredictable environments.

In contrast, passive harmonic filters use static components. These include inductors, capacitors, and resistors designed for specific frequencies. Consequently, their effectiveness can wane with varying loads or shifts in operating conditions.

AHFs offer several advantages:

- Real-time dynamic adjustment

- Higher precision in harmonic mitigation

- Improved power factor correction

- Compatibility with fluctuating loads

On the other hand, passive filters are simpler and often less expensive initially. They can be effective for stable environments with predictable harmonic loads. However, they do not offer the same level of adaptability and performance as AHFs.

Additionally, AHFs provide better protection for sensitive equipment. They are capable of reducing the risk of overheating and equipment failure. Meanwhile, passive filters may fail to mitigate effectively under certain conditions, leading to potential system issues.

While both filter types have their place, AHFs' superior adaptability and efficiency make them preferable for most dynamic environments. Whether for industrial, commercial, or critical infrastructure, AHFs deliver advanced power quality solutions tailored to modern electrical demands.

Integration and Installation Considerations

Integrating Active Harmonic Filters (AHFs) requires careful consideration of several factors. These devices can significantly improve power quality when implemented correctly. Understanding integration and installation nuances ensures optimal performance.

First, assess the existing electrical infrastructure. Determine the load types and harmonic levels present. This information guides AHF selection and configuration. A tailored approach is critical for effective harmonic mitigation.

Next, evaluate the available space for installation. AHFs come in different sizes and configurations. Ensure adequate room for installation and maintenance access. This planning prevents future operational challenges.

Consider the compatibility with existing systems. AHFs should integrate seamlessly into the current setup. Verify the AHF’s voltage and current ratings match those of the power system. Proper alignment ensures efficient operation.

Installation should be carried out by qualified professionals. The complexity of AHFs demands expertise in electrical systems. Professional installation minimizes risks and ensures compliance with safety standards.

- Assess electrical infrastructure and harmonic levels.

- Ensure space and accessibility for AHFs.

- Verify compatibility with existing systems.

- Hire qualified professionals for installation.

Finally, plan for future scalability. Industrial settings can change rapidly. Ensure the chosen AHF can handle potential increases in load and harmonic levels. This foresight safeguards long-term power quality.

By carefully considering these factors, businesses can maximize the benefits of AHFs. Proper integration and installation pave the way for improved energy efficiency, power factor, and system stability.

Technological Advancements in Active Harmonic Filters

Active Harmonic Filters (AHFs) have evolved significantly. Technological advancements have enhanced their efficiency and versatility. These improvements make AHFs crucial for modern power systems.

Recent innovations focus on real-time monitoring. This allows AHFs to adapt to fluctuating load conditions. Dynamic adjustments enhance harmonic mitigation and maintain optimal performance.

Newer AHFs are more energy-efficient. They reduce power consumption while improving power quality. These advancements contribute to greater energy savings and reduced operational costs. This efficiency is a major draw for industries.

Moreover, modern AHFs feature compact designs. Enhanced materials and engineering allow for smaller, yet powerful, units. Space constraints are no longer a barrier to implementation. This design evolution caters to diverse installation requirements.

Integration of smart technology is another trend. AHFs can now communicate with other power management systems. This connectivity supports centralized control and monitoring. Operational efficiency is boosted as a result.

Key technological advancements include:

- Real-time monitoring and dynamic adaptation.

- Increased energy efficiency with reduced power consumption.

- Compact designs for space-limited environments.

- Smart connectivity for enhanced system control.

With ongoing innovations, AHFs are set to become even more integral. Future developments promise further improvements in power quality and system efficiency. Staying updated with these advancements is essential for facilities aiming to optimize their electrical systems.

Case Studies: Real-World Benefits

Active Harmonic Filters (AHFs) are making tangible impacts across various sectors. Case studies reveal significant improvements in energy efficiency and power quality.

In one industrial facility, AHFs were installed to manage harmonic distortion. The facility noted a drastic reduction in their total harmonic distortion (THD). This improvement contributed to enhanced equipment performance.

Another example comes from a commercial building. The building faced challenges with non-linear loads affecting their power factor. By implementing AHFs, they achieved better power factor correction and reduced utility charges.

Energy savings are notable in manufacturing plants using AHFs. One plant reported energy savings of up to 15%. These savings resulted from reduced harmonic losses and optimized power usage.

Data centers also benefit significantly. AHFs help maintain stable power quality, protecting sensitive equipment. In one case, a data center experienced fewer outages and improved system reliability.

Key outcomes from these case studies include:

- Reduction in harmonic distortion levels.

- Enhanced equipment efficiency and longevity.

- Improved power factor and reduced utility charges.

- Increased energy savings and reduced operational costs.

- Greater system reliability and fewer equipment malfunctions.

Additionally, hospitals using AHFs have experienced improved power quality. This ensures critical medical equipment remains operational, thus safeguarding patient care.

AHFs have also helped a large retail chain achieve sustainability goals. By optimizing energy use and reducing waste, the chain lowered its carbon footprint.

These real-world applications emphasize the value of investing in AHFs. Businesses and institutions across various industries report significant benefits. Their experiences illustrate that AHFs are not just technical solutions, but strategic investments in power quality and efficiency.

Frequently Asked Questions about Active Harmonic Filters

Active Harmonic Filters (AHFs) may seem complex at first glance. However, understanding their core functions can clarify their importance. Below, we address some common queries about AHFs.

What is the main purpose of AHFs?

AHFs primarily aim to mitigate harmonic distortion in electrical systems. This leads to improvements in both energy efficiency and power quality.

How do AHFs enhance energy efficiency?

By reducing harmonic distortion, AHFs minimize energy loss. As a result, systems operate more efficiently, lowering energy waste and costs.

Here are some additional common questions:

- How do AHFs differ from passive filters?

- Are AHFs suitable for all types of facilities?

- Do AHFs require maintenance?

Where are AHFs most effectively used?

They are most beneficial in environments with non-linear loads. Examples include manufacturing plants, data centers, and commercial buildings.

Understanding these aspects of AHFs can help stakeholders make informed decisions. Proper use can lead to significant improvements in power systems and efficiency.

Conclusion:

The Future of Power Quality with Active Harmonic Filters

Active Harmonic Filters play a crucial role in modern electrical systems. They significantly enhance both energy efficiency and power quality. By mitigating harmonic distortion, they lead to more stable and reliable power systems.

Industries benefit from reduced operational costs and improved equipment longevity. This makes AHFs a wise investment for facilities with non-linear loads. Their ability to adapt to changing load conditions ensures systems operate optimally.

The future of power quality lies in innovative solutions like AHFs. As technology advances, AHFs will become even more efficient and compact. This evolution supports the growing demand for sustainable power solutions.

Incorporating AHFs into power quality strategies is essential for forward-thinking operations. Their contribution to energy savings and carbon footprint reduction cannot be overstated. As we move towards smarter grids, AHFs will be at the forefront of electrical efficiency and reliability.

- Why Is an Advanced Static Var Generator Becoming Essential for Modern Power Systems?

- Why did a cabinet-type active harmonic filter change the way my plant handles power quality?

- What makes a wall-mounted static var generator the smart fix for unstable power?

- Can Your Facility Meet Strict Grid Regulations with a Cabinet-Type Static Var Generator

- Does a Rack Mount Active Harmonic Filter Protect Against Transformer Damage

- Can a cabinet-type active harmonic filter turn hidden power losses into quick returns?