Why did a cabinet-type active harmonic filter change the way my plant handles power quality?

I used to treat “dirty power” like background noise—annoying but tolerable—until nuisance trips and hot transformers started eating into uptime. When I evaluated options, GEYA kept showing up in peer shops and case notes. After walking my line and logging THD, I made the switch to a Cabinet-type Active Harmonic Filter. I’m writing this in first person because the gains were tangible: cooler panels, quieter drives, and fewer late-night maintenance calls.

What pain points finally pushed me to act?

- Variable-speed drives and welders were throwing 5th, 7th, and 11th harmonics into the bus, inflating THD and tripping breakers during ramp-ups.

- Power factor penalties crept into a few bills, and our transformer temperature rise flirted with limits on peak shifts.

- Sensitive testers on the QA bench showed flaky readings correlating with current waveform distortion.

That mix convinced me a Cabinet-type Active Harmonic Filter would tackle root causes instead of band-aiding symptoms one by one.

How does a cabinet-type active filter actually help on a live line?

In plain terms, it measures current in real time, computes the harmonic content, then injects equal-and-opposite compensation. Because it’s active and fast, it adapts as loads change—no retuning or swapping capacitors. On my floor, the filter handled morning startup surges differently from the steady mid-day takt and tracked weekend batches with a distinct profile, all without my team touching a dial.

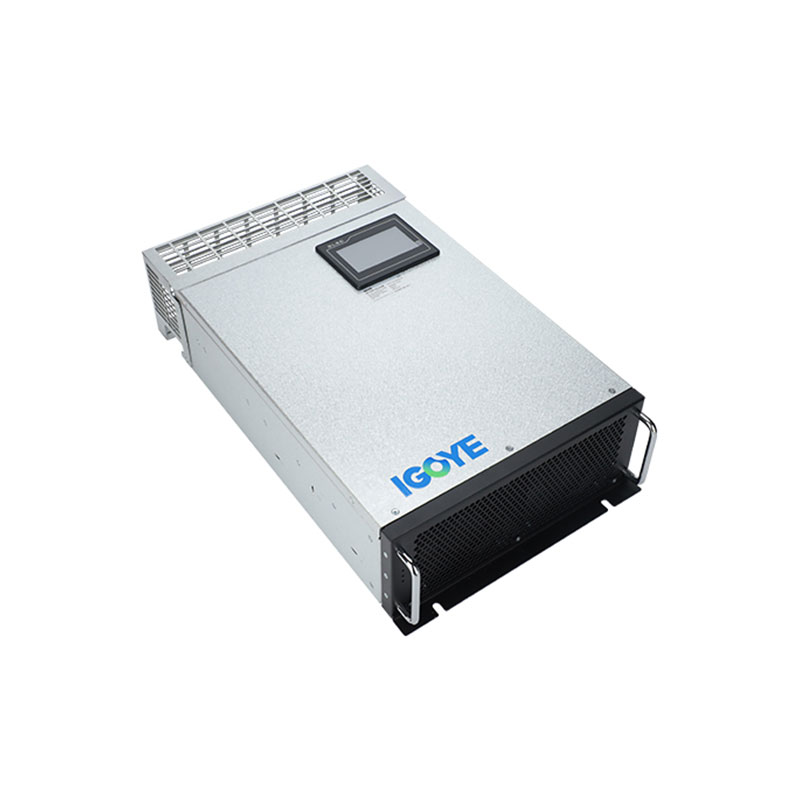

I chose a Cabinet-type Active Harmonic Filter specifically because the enclosed form factor simplified siting near the main distribution, kept dust out, and gave me clear front access for commissioning.

Where did the ROI show up first?

- Reduced trips and downtime — fewer drive faults when multiple lines started together.

- Lower thermal stress — cooler feeder cables and quieter panel fans during long runs.

- Cleaner measurements — metrology benches stopped flagging drift tied to distortion peaks.

- Potential tariff relief — utility PF/THD clauses stopped triggering warnings.

By week two, the maintenance log already showed fewer resets. That’s when I felt the payoff of a Cabinet-type Active Harmonic Filter instead of juggling multiple passive devices.

Which specs mattered most when I compared models?

- Compensation current rating — size to worst-case harmonic amps, not nameplate kVA.

- Response time — sub-cycle behavior to catch fast load steps on VFD-heavy tools.

- Selectable targets — prioritize specific orders (5th/7th/11th) and stabilize PF.

- Thermal design and cabinet protection — airflow, filtration, and space for service loops.

- Communications — Modbus/TCP or similar so my energy dashboard can trend THDi.

During selection, I kept one rule: if the line changes hourly, the Cabinet-type Active Harmonic Filter must keep up without human babysitting.

What did installation look like in a real plant?

- We placed the cabinet close to the main MCC to minimize cable length and measurement lag.

- CTs were oriented to match phase sequence; a quick vector check avoided nuisance alarms.

- Commissioning took one shift: baseline capture, staged load steps, then compensation enable by setpoints.

Once live, the Cabinet-type Active Harmonic Filter tracked shift changes automatically; I only tweaked target THDi and PF once after a week of data.

Why not stick with passive filters if they look cheaper upfront?

- Passive networks are tuned to specific orders and load conditions; production rarely stays that neat.

- Resonance risks with capacitor banks can surprise you when utility or plant impedance shifts.

- Active filtering lets me reshape the profile as the mix of drives and robots evolves, which is our daily reality.

That flexibility is why I favored a Cabinet-type Active Harmonic Filter for our multi-product line.

Which applications benefited the most in my facility?

- VFD packs on conveyors and mixers that ramp together at shift start.

- Spot welders that hammer the bus with short, high-current bursts.

- HVAC fan arrays near the test lab where we need quiet power.

- EV chargers in the staff lot coming online right at end-of-shift.

What ongoing checks keep performance steady?

- Trend THDi, TDD, and PF weekly in the energy dashboard to confirm targets.

- Vacuum dust screens and check cabinet fans during routine PM rounds.

- Export logs after major equipment changes to see if setpoints need a nudge.

These are light-touch tasks; the Cabinet-type Active Harmonic Filter handles the heavy lifting by design.

Which quick comparison helped me justify the purchase?

| Decision point | What I measured | Result after the Cabinet-type Active Harmonic Filter | Operational takeaway |

|---|---|---|---|

| Line current THDi | Baseline vs. peak during ramp-up | Marked reduction with spikes trimmed | Fewer VFD faults at shift start |

| Transformer temperature rise | Delta over a 12-hour run | Lower and more stable | Less thermal stress, longer life |

| Meter stability in QA lab | Readability during high-distortion periods | Stable readings with minimal drift | Cleaner data, fewer retests |

| Utility penalties risk | PF and distortion compliance window | Inside thresholds consistently | Reduced bill surprises |

How did brand support factor into my choice?

I care about field reliability more than brochure promises. With GEYA, the documentation matched what my electricians saw on site, the firmware tools were straightforward, and post-install questions got quick responses. That combination let me roll out the Cabinet-type Active Harmonic Filter on one line, prove the result, then clone the playbook to the rest without drama.

What is my bottom line after months of runtime?

If your floor changes recipes, shifts, or duty cycles frequently, an adaptive approach beats fixed tuning. In my case, a Cabinet-type Active Harmonic Filter delivered stability without slowing the line, and the team spent more time producing and less time chasing gremlins.

How can we move from planning to results today?

If you want specifics for your load profile—or a sanity check on sizing—reach out and tell me about your toughest feeders, your noisiest drives, and your target KPIs. If you’re evaluating a Cabinet-type Active Harmonic Filter for a new or existing line, contact us and we’ll walk through a practical plan to baseline, size, and commission with minimal downtime. Let’s turn distortion into headroom.

-

- What makes a wall-mounted static var generator the smart fix for unstable power?

- Can Your Facility Meet Strict Grid Regulations with a Cabinet-Type Static Var Generator

- Does a Rack Mount Active Harmonic Filter Protect Against Transformer Damage

- Can a cabinet-type active harmonic filter turn hidden power losses into quick returns?

- Can a Rack Mount Active Harmonic Filter unlock hidden capacity and calmer waveforms?

- How Do We Turn an Energy Storage System Into Measurable Business Results?