Where can an Active Harmonic Filter make the biggest difference today?

I spend most of my week immersed in factories running variable frequency drives, uninterruptible power supplies and rapid charging equipment, so I care less about buzzwords and more about solutions that stand up to the Monday morning test. Over time I grew to trust partners like GEYA for dependable low-voltage gear, and I keep reaching for an Active Harmonic Filter when the brief is simple yet brutal. Keep production up, keep the utility calm, keep the cables cool. Here is how I approach the problem and what I learned in the field.

Why do trips, hot cables, and humming transformers show up when production scales?

- I see non-sinusoidal current from VFDs, six-pulse rectifiers, UPSs, and fast chargers that pushes THDi well above comfortable numbers.

- Neutral conductors run warm because of triplen harmonics, especially on three-phase four-wire systems feeding single-phase IT loads.

- Capacitor banks detuned for resonance still get punished by harmonic current and die early.

- Protection settings look fine on paper, yet nuisance trips persist because of distorted waveforms and crest factors.

What problems do I expect an Active Harmonic Filter to solve in the real world?

- Pull THDi down toward a target that aligns with site policy and utility limits while keeping THDv stable.

- Provide dynamic reactive power support to clean up power factor during variable loading.

- Kill specific harmonic orders that upset generators or transformers in microgrids.

- Share load across multiple cabinets without fragile manual balancing.

How do I decide between an AHF, a passive filter, an active front end, or a multi-pulse rectifier?

I start with the mix of loads, the variability of the duty cycle, and the space I have at the switchboard. I keep this comparison close when I talk to stakeholders.

| Option | Typical THDi outcome | Response to load changes | Footprint and retrofit ease | Capex and Opex view | When I pick it |

|---|---|---|---|---|---|

| Active Harmonic Filter | ~5–10% with correct sizing and CT placement | Real-time dynamic compensation | Compact wall or floor cabinet, easy retrofit at MCC or MSB | Mid capex, low hassle, high flexibility | Mixed loads, fast duty swings, brownfield projects |

| Passive harmonic filter | Good on tuned orders, weaker off-tune | Fixed response, sensitive to system shifts | Medium footprint with detuned caps and reactors | Low capex, higher risk of detune or resonance | Stable single-load applications with known spectrum |

| Active front end drive | Low THDi per drive | Excellent per-drive behavior | Changes each drive, not central | Higher capex per asset | New builds where drive replacement is on the table |

| 12-pulse or 18-pulse rectifier | Moderate to good, depends on balance | Better than six-pulse yet not dynamic | Bulky transformers, more copper | Medium to high capex | Large constant loads with room for transformers |

Where should I place the AHF and how do I avoid CT mistakes?

- I mount the AHF close to the bus I want to clean to cut impedance between filter and load.

- I place CTs on the same bus the AHF is compensating and keep polarity consistent with the manual. I label S1 and S2 during install, no shortcuts.

- I verify phase rotation and compensation direction with a staged load test before I leave the site.

How do I size the cabinet without throwing money at nameplate numbers?

- I measure true RMS and harmonic spectrum at several duty points, not just a five-minute snapshot.

- I size to the vector sum of target orders plus a headroom factor for growth and temperature.

- I treat reactive power support as a bonus, not a substitute for proper kVA sizing.

| Application | Starting point for AHF current rating | Typical target THDi | Notes from field work |

|---|---|---|---|

| Mixed VFD process line | 35–50% of bus current | < 10% | Spread across two cabinets for redundancy |

| Data center UPS input | 30–40% of UPS input current | < 8% | Watch neutral triplen current on 4-wire systems |

| EV fast charging hub | 40–60% of feeder current | < 8% | Plan for charger diversity and future bays |

| Rooftop solar with inverters | 20–35% of inverter AC rating | < 8–10% | Check flicker limits during ramp events |

Can one central cabinet handle the whole board or should I go distributed?

I split compensation when cables are long and when large step loads sit on distant feeders. Central works well when the main bus supplies mostly local loads and the spectra look similar. Distributed shines in sprawl and in sites with multiple harmonic personalities.

What about standards and utility requirements I actually need to pass?

- I benchmark against site rules that mirror common harmonic limits for current at the PCC.

- I verify compatibility with generator operation in island mode for microgrids.

- I document before and after results with the same analyzer and time window so the utility engineer sees apples to apples.

Which hidden constraints slow projects more than hardware lead time?

- Ventilation and dust. I derate for temperature and specify filters that a tech can clean in minutes.

- Earthing integrity. I verify bonding and cable shields because high-frequency currents need a clean return path.

- Communications. I decide early whether I expose data over Modbus TCP, BACnet, or a simple dry-contact set for BMS alarms.

How do I make the business case that finance will accept?

- I calculate avoided downtime from nuisance trips and drive faults.

- I add lifetime gains from cooler conductors, longer capacitor life, and lower transformer noise and copper losses.

- I include utility penalties avoided and the risk reduction during audits.

| Pain point I hear | What I check first | Action I usually take | Expected outcome |

|---|---|---|---|

| Breakers trip on busy shifts | THDi trend vs load and crest factor | Right-size AHF and tune orders | Stable runs and fewer resets |

| Transformers buzz and run warm | Voltage distortion and K-factor | Central AHF near the transformer | Lower noise and temperature |

| Cap banks keep failing early | Resonance near 5th or 7th | AHF plus detuned bank check | Longer capacitor life |

| Utility warning letters | Compliance data at PCC | Before and after report with logs | Clear evidence of improvement |

What does a clean commissioning plan look like without drama?

- Capture baseline over a representative production window.

- Confirm CT orientation, phase rotation, and comms.

- Enable compensation in steps while logging waveforms.

- Validate targets during worst-case duty and photograph analyzer screens for the report.

- Hand over a one-page quick guide for operations and a quarterly check routine.

How do I extend the idea beyond low voltage and into tougher environments?

- For marine and oil and gas I favor enclosed designs with coated boards and higher ingress ratings.

- For medium voltage I consider cascaded solutions that use LV AHFs on feeder secondaries to avoid MV complexity.

- For noisy IT rooms I use cabinets with low acoustic profiles and keep airflow front to top to fit hot aisle and cold aisle rules.

What should I ask a vendor before I issue a PO?

- Can I see logged real site results for a load profile similar to mine

- How does the cabinet share load when I parallel units

- What is the thermal derating curve and the replacement path for fans

- Which harmonic orders can I prioritize and how quickly do settings change under load

- Can the unit provide both harmonic mitigation and dynamic reactive support without conflicts

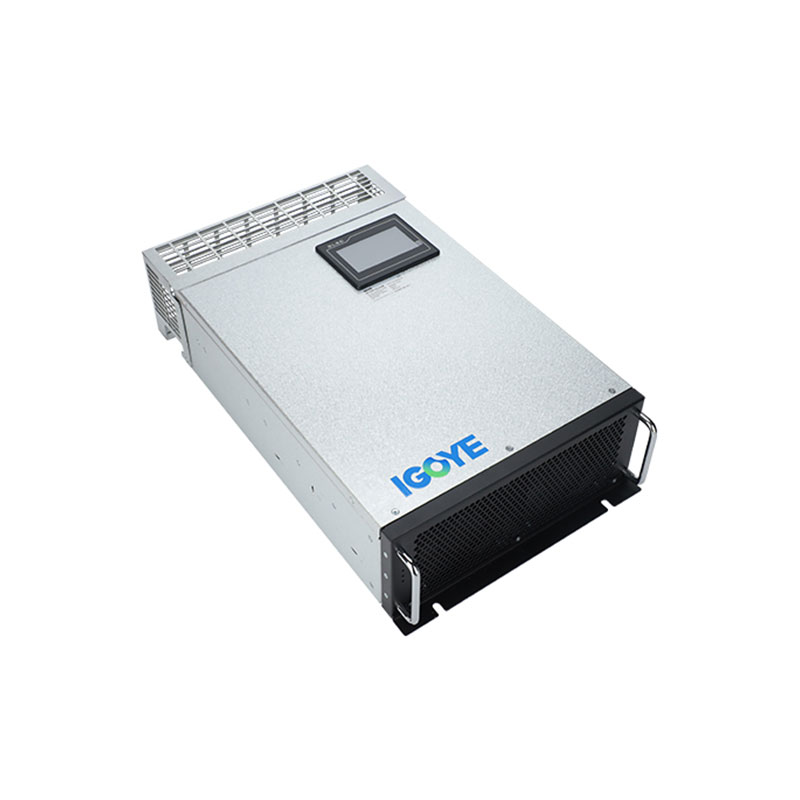

Would I use a GEYA AHF for my next brownfield upgrade

Yes when the board space is short, the load mix is messy, and the goal is fast compliance with clear data. I like that I can place the cabinet close to the problem bus, scale in parallel, and keep options open as equipment changes over time.

Shall we talk about your site and targets

If you want a practical review of your spectrum, sizing, and placement, I am happy to look at drawings and a week of logs. If you are exploring a pilot, reach out and we can map a clean path from measurement to commissioning. Contact us to discuss measurements, sizing, and commissioning steps. Send your inquiry and I will reply with a tailored proposal and an expected improvement range for your site.

- Benefits of Using Active Harmonic Filters

- Why Is an Advanced Static Var Generator Becoming Essential for Modern Power Systems?

- Why did a cabinet-type active harmonic filter change the way my plant handles power quality?

- What makes a wall-mounted static var generator the smart fix for unstable power?

- Can Your Facility Meet Strict Grid Regulations with a Cabinet-Type Static Var Generator

- Does a Rack Mount Active Harmonic Filter Protect Against Transformer Damage