Can a Rack Mount Active Harmonic Filter unlock hidden capacity and calmer waveforms?

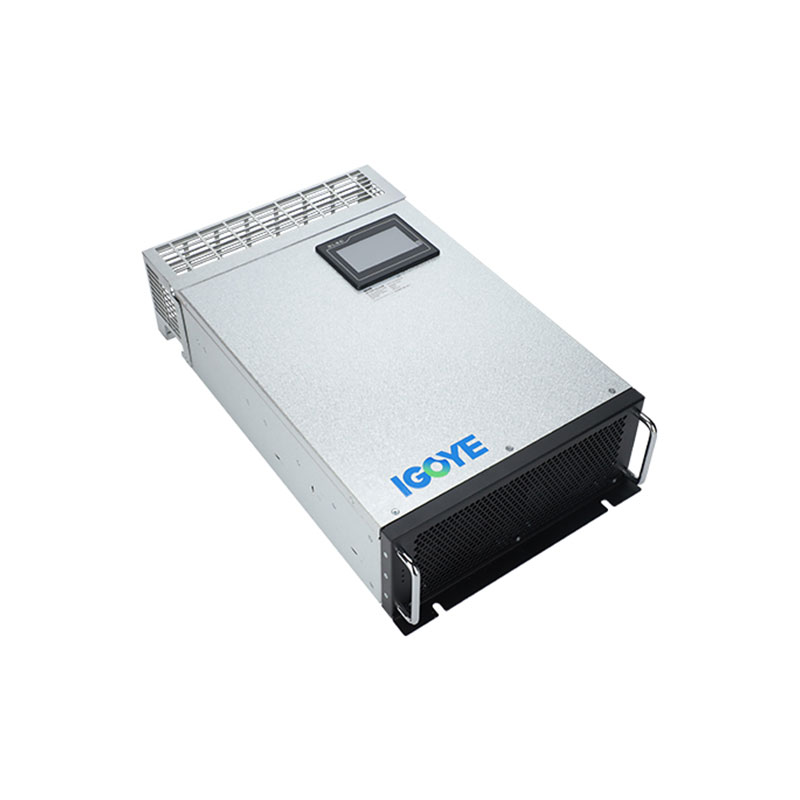

I walked into a panel that sounded like a beehive: VFDs ramping, welders spiking, servers humming. Instead of planning a bigger transformer, I tried a smarter fix. With support from GEYA, I dropped in a Rack Mount Active Harmonic Filter that lives in a 19-inch slot, watches the current in real time, and injects the precise counter-current that cleans distortion, levels phase loading, and adds fast reactive support. The bus stopped buzzing; headroom appeared where I thought none existed.

Why does “good enough” power quietly waste money and life on your equipment?

Neutral conductors run hot, breakers nuisance trip, motors run a little rough, and tariffs creep up because the bill dislikes poor power factor. When I cleaned the spectrum, I recovered usable capacity without touching upstream gear. That is where the Rack Mount Active Harmonic Filter proved itself—less heat, fewer resets, friendlier utility bills.

- Cooler cables and transformers preserve insulation life

- Fewer drive and UPS trips improve uptime

- Higher PF reduces penalties and frees margin for growth

What makes an active approach beat passive traps when the load mix never sits still?

Passive networks chase fixed orders and can detune as the lineup changes. An active unit measures each cycle and cancels what is actually present. In my cabinet, the Rack Mount Active Harmonic Filter adjusted on the fly as presses, chargers, and servers took turns peaking, so I did not need three different filters for three different shifts.

- Wide-band cancellation rather than a few narrow notches

- Dynamic vars follow the feeder instead of overcorrecting

- No awkward resonance with capacitor banks when set correctly

How did I size it without turning the project into a science fair?

I scoped the worst five-minute windows, not the calm average, then sized the Rack Mount Active Harmonic Filter to that reality. Commissioning took an afternoon because wiring stayed short and access was right at the rack.

- Measure peaks during real production, not lunch break

- Allow diversity across feeders so you avoid oversizing

- Mount CTs with correct orientation and tighten them before energizing

- Enable compensation in steps while logging for a week

| What I checked | Why it mattered | Rule of thumb I used |

|---|---|---|

| Compensation current | Ceiling for cancellable distortion | Size to peak THDi amps in the ugliest 5–10 minutes |

| Harmonic orders covered | How broadly the spectrum gets cleaned | Include higher orders common to VFD and rectifier fronts |

| Reactive support range | PF improvement without extra capacitor banks | Account for inductive swings when big motors start |

| Thermal and airflow | Stable correction at high duty cycles | Leave intake and exhaust space in the rack plan |

| Rack fit and service space | True “drop-in” installation | Confirm depth, bend radius, and front access for modules |

What did a week of data say after the change?

Every site is different, but the pattern repeats: lower THDi, calmer voltage at the PCC, better power factor. After installing the Rack Mount Active Harmonic Filter, I saw fewer resets and cooler transformers during peak heat—quiet victories that add up fast.

| Metric | Before | After | What it told me |

|---|---|---|---|

| Feeder THDi | High double-digit swings on shift changes | Single-digit range under the same load | Distortion shrank where it hurts most |

| Power factor | Below contract target in busy hours | At or above target most of the day | Less penalty exposure and more usable capacity |

| Equipment trips | Sporadic, especially on VFD ramps | Rare post-tuning | Stability improved without touching drives |

| Transformer temp | Noticeably higher during hot spells | Lower and steadier | Thermal stress eased |

Where does the payback actually appear on a normal P&L?

- Tariff relief when PF and distortion stay inside your band

- Fewer resets and scrap during production sprints

- Deferred upgrades because freed capacity covers the next expansion

- Longer asset life from cooler conductors and transformers

Which sites feel the gains fastest in my experience?

- Drive-heavy manufacturing like printing, textiles, CNC

- Data rooms and labs that dislike voltage wobble

- Hospitals with imaging plus UPS handoffs

- EV charging clusters with spiky, asymmetric demand

Across all four, the Rack Mount Active Harmonic Filter kept the bus composed while loads surged and faded.

Why did I prefer a rack unit over a floor cabinet for this retrofit?

- Short cable runs and tidy routing right next to the offenders

- Modular service without rearranging the room

- Familiar 19-inch infrastructure that speeds deployment

That practicality is why I keep choosing a Rack Mount Active Harmonic Filter when space is tight and timelines are tighter.

What should you do if you need cleaner power before the quarter closes?

If you want sizing help or a quick pilot plan, I can walk you through the same checklist I used with GEYA and tailor it to your panel layout. Leave an inquiry with your feeder ratings, space limits, and PF targets, and we will map a focused trial that proves value quickly—contact us today.

- Benefits of Using Active Harmonic Filters

- Why Is an Advanced Static Var Generator Becoming Essential for Modern Power Systems?

- Why did a cabinet-type active harmonic filter change the way my plant handles power quality?

- What makes a wall-mounted static var generator the smart fix for unstable power?

- Can Your Facility Meet Strict Grid Regulations with a Cabinet-Type Static Var Generator

- Does a Rack Mount Active Harmonic Filter Protect Against Transformer Damage