How Does a Rack Mount Active Harmonic Filter Improve Power Quality?

Article Summary

In modern electrical systems, harmonic distortion creates inefficiencies, unwanted heat, and operational risks. A rack mount active harmonic filter provides a targeted solution by detecting and mitigating harmonics in real time. This article explains what these filters do, how they work in rack environments, their benefits, installation considerations, performance metrics, and answers frequent questions to help you make informed decisions for improving power quality across your facility.

Table of Contents

Overview of Harmonic Distortion

Harmonic distortion refers to waveform irregularities introduced into an electrical system when non-linear devices draw current in abrupt pulses rather than in smooth sine waves. Common sources include variable frequency drives, rectifiers, server power supplies, and other modern equipment that are standard in data centers and industrial control racks.

These distortions affect power quality and can lead to overheating, equipment stress, inefficiencies, and premature failure. The result is not only degraded system performance but also increased maintenance and utility costs.

What Is a Rack Mount Active Harmonic Filter?

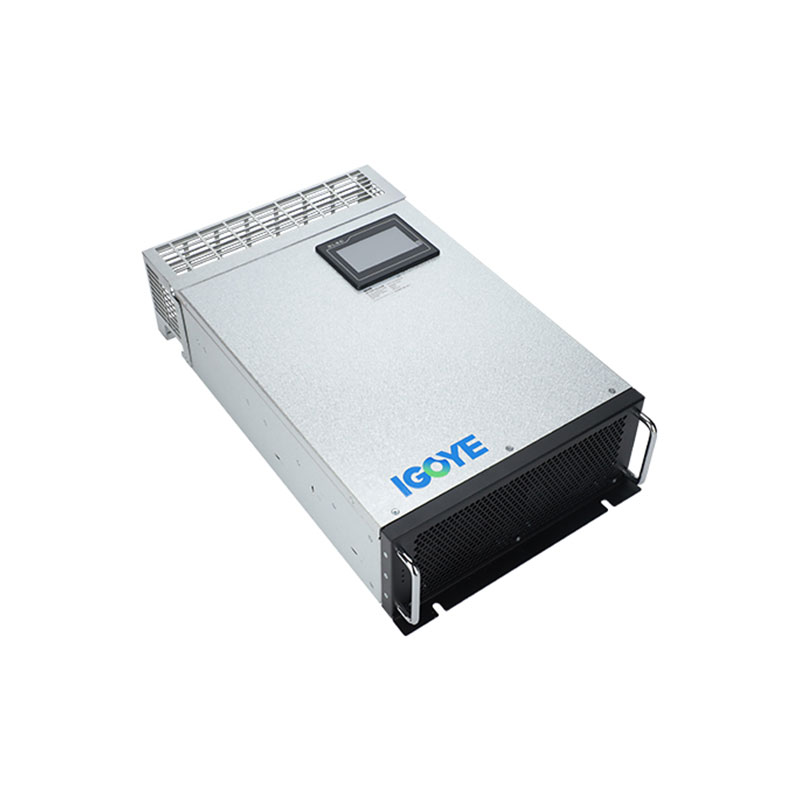

A rack mount active harmonic filter is a compact, high-performance device designed to be installed within standard 19" or 23" equipment racks. It continuously monitors electrical currents and injects compensating currents to counteract harmonic distortion. Unlike passive filters, which use fixed components tuned for specific harmonics, an active filter dynamically adjusts to changing load conditions.

These units are especially suitable for environments where space is limited and power quality demands are high, such as data centers, telecommunication hubs, and industrial control panels.

How an Active Harmonic Filter Works

Active harmonic filters operate on a real-time control loop principle. They measure the total current waveform, isolate the harmonic components, and generate an inverse signal to neutralize the unwanted frequencies. The result is a cleaner, closer-to-ideal sine wave output for the load.

| Step | Process | Outcome |

|---|---|---|

| 1 | Current waveform analysis | Detection of harmonic frequencies |

| 2 | Calculation of compensation waveform | Determination of inverse signal |

| 3 | Injection of compensating current | Reduction of harmonic distortion |

| 4 | Continuous feedback adjustment | Real-time performance optimization |

Key Benefits for Rack Systems

Below are the primary advantages you gain by integrating a rack mount active harmonic filter into your electrical infrastructure:

- Improved Power Quality: Lowers total harmonic distortion (THD), stabilizing voltages and currents.

- Reduced Equipment Stress: Minimizes overheating in transformers, cables, and critical loads.

- Enhanced System Reliability: Helps prevent false tripping and unexpected system downtime.

- Energy Efficiency: Reduces non-productive power usage and decreases electrical losses.

- Space Saving: Rack-mountable design conserves floor space and integrates easily with existing infrastructure.

Selection and Installation Checklist

Choosing the right filter and ensuring proper installation will determine the success of your power quality upgrade. Use the checklist below for guidance:

- Load Profile Assessment: Evaluate typical and peak load conditions.

- Harmonic Level Measurement: Record current THD levels for baseline comparison.

- Filter Capacity Match: Verify that filtering capacity meets or exceeds expected harmonic load.

- Rack Space Availability: Confirm compatible rack mounting unit height (U-size) and depth clearance.

- Cooling and Ventilation: Provide adequate airflow to prevent overheating of active electronic components.

- Integration with Monitoring Systems: Ensure communication compatibility for remote monitoring and alerts.

Performance Metrics Explained

Understanding performance data helps evaluate filter effectiveness. The table below highlights typical key metrics used by engineers and purchasing professionals.

| Metric | Definition | Importance |

|---|---|---|

| Total Harmonic Distortion (THD) | Percentage deviation from the ideal waveform | Indicates reduction in waveform distortion |

| Response Time | Time taken to compensate for harmonic changes | Affects real-time filtering performance |

| Filter Capacity (kVAR) | Maximum reactive power the filter can handle | Determines suitability for load conditions |

Frequently Asked Questions

Q1: How fast does a rack mount active harmonic filter respond to changes?

A: Response time varies by model and load but modern active filters operate with millisecond-level adjustments to maintain waveform quality under dynamic conditions.

Q2: Can this filter operate with three-phase systems?

A: Yes, most rack mount active harmonic filters are designed for three-phase distribution circuits commonly found in industrial and data center applications.

Q3: Does installation require system shutdown?

A: While some installations can occur during maintenance windows, qualified electricians can perform plug-in or parallel installations with minimal disruption when designed properly.

Q4: What maintenance is required?

A: Periodic inspection, dust removal, and verification of connection integrity are typically sufficient; many units also provide alerts when service is recommended.

Conclusion

A rack mount active harmonic filter is a practical solution for facilities seeking significant improvement in power quality without dedicating large floor space to equipment. By dynamically adjusting to harmonic conditions, it protects critical systems, enhances efficiency, and supports operational continuity in environments with sensitive electrical infrastructure.

GEYA offers a range of rack mount active harmonic filters engineered for reliability and performance. For tailored advice and system integration support, contact us to discuss your specific power quality challenges and how GEYA solutions can help you achieve dependable, efficient electrical operations.

-

- Benefits of Using Active Harmonic Filters

- Why Is an Advanced Static Var Generator Becoming Essential for Modern Power Systems?

- Why did a cabinet-type active harmonic filter change the way my plant handles power quality?

- What makes a wall-mounted static var generator the smart fix for unstable power?

- Can Your Facility Meet Strict Grid Regulations with a Cabinet-Type Static Var Generator

- Does a Rack Mount Active Harmonic Filter Protect Against Transformer Damage